Vaporization plant

About the vaporization plant

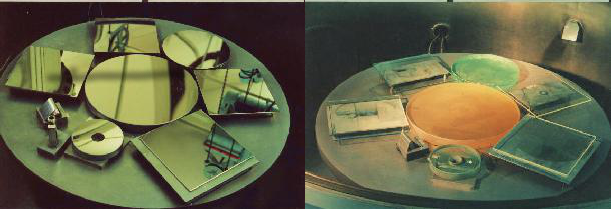

With the construction of the Large Hamburg Schmidt-Mirror a vaporization plant by Leybold was installed in the same building (today the building houses the Oskar-Lühning-telescope). The spacious plant can service Schmidt mirrors up to 123cm in diameter and parabolic mirrors up to 100cm. Thus it was suited for the later constructed 120cm Oskar-Lühning telescope. 1987/1988 the plant was refurbished with funds from DFG. In particular the vacuum pumps needed replacement. The thus far largest serviced item was the 132cm mirror of the Skinakas-Observatory of the University of Crete.

Telescope mirrors are typically made of glass that is highly precisely polished into a parabolic or spherical shape. On this glass foundation a highly reflective aluminium coat is applied. This involves a vaccuum bell jar of 153cm diameter that is evacuated to a pressure of 7·10-5 mbar (one fifteen millionth of normal air pressure with the glas bodies inside. In case of a re-coating process the old layer needs to be removed with lye, first. Each coating involves the vaporization of about 1 cm3 = 2,7 grams of aluminium at 2500° C within approximately 2 minutes. The layer of highly reflecting (88%) aluminium condensing on the glass reaches a thickness of roughly 50-100 nanometers.

Mirror coating (Conditions and Pricing)

Die Hamburg Observatory offers mirror coating services. Our vaporization plant fits mirrors of up to 150 cm in diameter, though for mirrors of 120cm and up technical limitations might prevent it from fitting which is why we recommend previous consultation. Mirrors will be coated with aluminium with an optional protective silicon layer.

Pricing for mirror coating can be found in the table below.

Terms and Conditions:

Responsibility for transport and delivery of mirrors to the Hamburg Observatory is in the hands of the customers. In case of large mirrors please consult us in order to ensure that necessary equipment for unloading operations is available. The Hamburg Observatory takes responsibility for proper coating of the mirror but responsibility for transportation, including on observatory grounds, is with customers.

Pricing for vaporizations:

| diameter | prices (excluding VAT) |

| 5cm | 35€ |

| 10cm | 70€ |

| 15cm | 105€ |

| 20cm | 140€ |

| 25cm | 185€ |

| 30cm | 210€ |

| 35cm | 245€ |

| 40cm | 280€ |

| 45cm | 360€ |

| diameter | prices (excluding VAT) |

| 50cm | 450€ |

| 55cm | 550€ |

| 60cm | 660€ |

| 65cm | 1100€ |

| 70cm | 1750€ |

| 75cm | 2400€ |

| 80cm | 3200€ |

| 85cm | 4080€ |

| 90cm | 4680€ |

| diameter | prices (excluding VAT) |

| 95cm | 5510€ |

| 100cm | 6600€ |

| 105cm | 7665€ |

| 110cm | 8800€ |

| 115cm | 9890€ |

| 120cm | 11040€ |

| 125cm | 11750€ |

| 130cm | 13000€ |

| >130cm | request |