4K-5T-UHV-AFM System

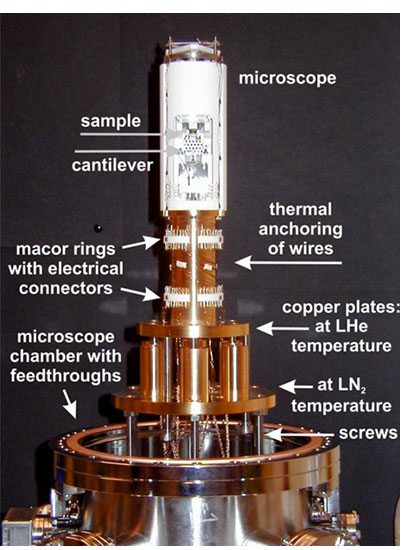

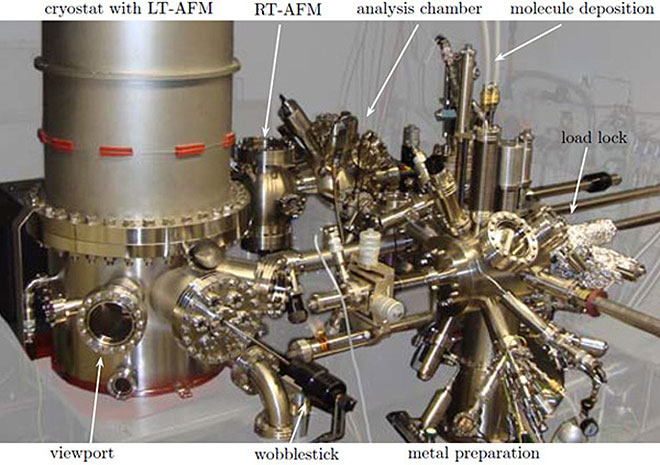

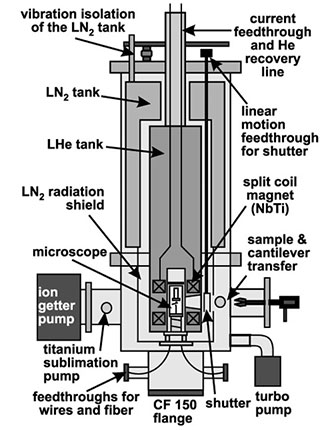

The UHV-System (see Fig. 1) consists of a load lock, a metal preparation chamber, a molecule preparation chamber an analysis chamber and a cryostat chamber. Tips and samples are introduced via the load lock, which is also equipped with crystal cleavage station. In the metal preparation chamber evaporators can be loaded with different metals to coat probes or to growth thin films on metallic substrates. Metallic substrates can be cleaned with sputter-anneal-cycles or glowing in oxygen and flashing at temperatures above 2000°C. Molecule deposition from an exchangeable crucible takes place in a separate chamber with its own heating station. Surface quality can be controlled in the analysis chamber with a LEED/AES unit and a room temperature AFM/STM. The cryostat chamber (see Fig. 2) houses a UHV-compatible 4He bath cryostat with a home build AFM (see Fig. 3) [4] located in the center of a 5 T split coil superconducting magnet. This configuration allows side access to exchange tip and sample in-situ without moving the microscope. After opening the shutter thermal equilibrium is reached with 1 hour.

To shield the microscope from vibration several precaution are implemented. (i) Data acquisition and operator are located in different room next to the lab. (ii) The lab space is sound protected and has a separate foundation. Additionally, the UHV system is supported by vibration isolation legs. (iii) Solidification of the liquid nitrogen in the radiation shield around the helium tank by pumping prevents bubbling noise. The pump itself is located in a separate room and isolated from the floor by damping legs.