Additive manufacturing with nanomaterials

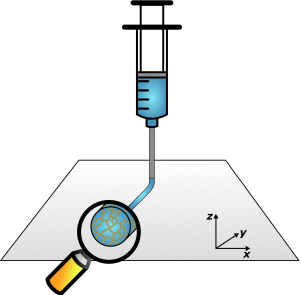

Additive manufacturing, commonly known as 3D printing, is a process in which materials are added layer-by-layer to create objects of various shapes. The ability to pattern the structure of materials in three dimensions enables new opportunities in terms of designing and cost-efficient manufacturing of multicomponent materials with a hierarchical architecture, which has not been possible so far by any other fabrication techniques.

By processing nanoscopic building blocks into inks, macroscopic 3D structures can be printed which conserve the unique and versatile properties of nanomaterials in a macroscopic device. For example, we have successfully utilized TiO2 nanoparticle-based aerogels as additive-free inks for 3D-printing. The TiO2 gels have been loaded with plasmonic Au nanorods to facilitate local photothermal heating of the aerogel. Furthermore, the TiO2 aerogels have been applied in photocatalytic water splitting where periodic 3D microstructuring enhances the gas permeability compared to a monolithic aerogel, while maintaining the high light-harvesting efficiency of the nanoporous material.

In general, diverse colloidal nanomaterials can be processed into inks and 3D printed, thus giving access to multifunctional aerogels with full control of the nano-, micro-, and macroscopic length scales. The aim of the project is to make more materials available for 3D printing, improving the method further and finding new applications for the printed structures, such as the catalytic reduction of CO2.

Contact for this project: Matthias Rebber, Malte-Maximilian Schmidt

Publications:

Additive‐Free, Gelled Nanoinks as a 3D Printing Toolbox for Hierarchically Structured Bulk Aerogels

Rebber M., Trommler M., Lokteva I., Ehteram S., Schropp A., König S., Fröba M., Koziej D.

09.02.2022, In: Advanced Functional Materials. 32, 19, p. 2112914